Our slogan “Create it, we make it

Our company is constantly developing practical solutions for all our customers’ projects, supporting them right through to the final production of their turnkey products.

Baudouin DUPONT (FR)

Président

Sang-Hoon LEE (KR)

Manager factory Korea

Micheal & Michaela ROOS (DE)

Eyewear with no Frontier (DE + FR)

Brillen ohne Grenzen (DE)

Lunettes sans Frontière (FR)

Founded in 1992, Dailytec-Kycloth is the leading Franco-Korean manufacturer of high-end microfiber textiles, distributed through a number of branches, mainly in Europe.

Located in the city of Daegu in South Korea, our factory has a production capacity of 1.2 million metres per year (100,000 metres per month) and a turnover of 5.3 million Euros, representing several million pieces of microfiber cut per year, and growing every year. Production is fully automated and our 43 employees (33 at the factory and 10 for export) are committed to producing outstanding quality while offering customers a personalised, multilingual service via our subsidiaries in Europe.

In the current global economic market, our factory has won several awards from government authorities for its export dynamism and the quality of its products, which is recognised by all our customers around the world.

In addition, all our high quality microfibers are free from toxic products.

Our high-market microfibers are widely used in many fields, often requiring the cleaning of delicate surfaces :

In addition to their amazing cleaning efficiency, all our microfibers are creative and effective communication items for promotional advertising in over 120 different markets.

Everything, from weaving and knitting, custom printing and packaging to delivery, is done in-house at our factory to ensure top quality and on-time delivery.

Video of our factory in Korea

Our international team of professionals is at your service to:

With a 360 ° vision our specialists help you in defining the needs and their implementation. Your projects are supported until delivery to your home.

Most of our machines are from Germany and operate according to most advanced techniques.

The microfiber yarns used in our productions are the finest yarns in the world (75 and 120 deniers) what ensures an amazing cleaning efficiency of all delicate surfaces and a very high resolution by digital printing.

The entire production process is fully integrated in our factory, from yarn knitting to high-tech digital printing, including cutting, sewing and individual packaging.

All our customized microfibers are printed using state-of-the-art technology, giving the products effective communication and efficient cleaning qualities in the promotional and optical sectors.

Customization to meet our customers’ specific expectations and needs. Highly practical and indispensable in everyday life, they ensure that your advertising message is constantly visible.

Traditional lens cloths for screens and optics – pouches for watches and glasses – soft and hard cases – cosmetic pads – gloves – photo bags – multi-purpose towels – mouse pads – postcards – key rings – miscellaneous items.

Traditional lens cleaning cloths for screens and optics – – mouse pads – pouches for watches and glasses – soft and hard cases – cosmetic pads – gloves – multipurpose towels – photo bags – mouse pads – postcards – photo bags – keyrings – and many more.

Our company has developed in many fields of communication in more than 120 different markets : events – optics – labs – medicine – pharma – sports – tourism – museums – casinos – administrations – universities – IT – banks – telecom – insurance – transport – employment agencies – hunting – fishing – press and magazines – services – industries – various…

Unlimited creativity of products, images, sizes and colours.

4-colour digital printing, 1 or 2-colour screen printing for logos, heat embossing, silicone or acrylic dots.

A variety of finishes (zig-zag or straight cut, straight round cut, customized cuttings in

special shapes, stitching, etc.).

Targeted advertising and promotional communications in all economic sectors.

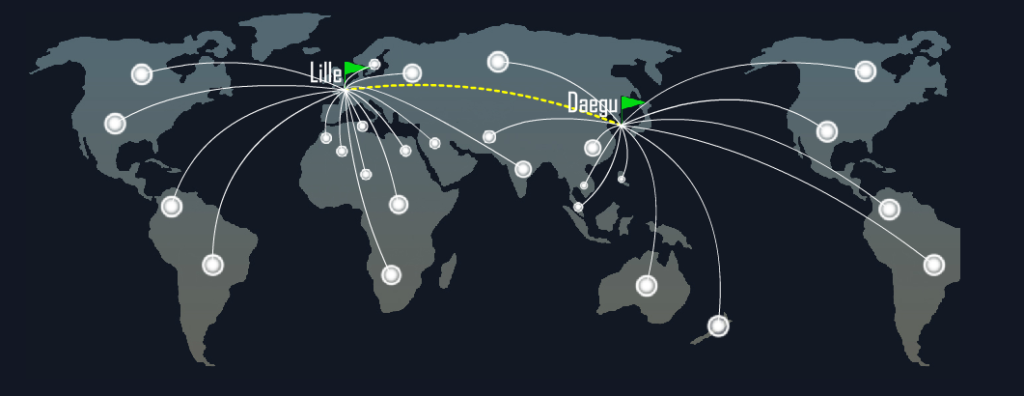

With a production capacity of 1.2 million meters of microfibers per year, which represents hundreds of millions of cut microfibers, and a turnover of 5.3 million Euros, our microfibers are exported to over 100 countries throughout the world to around 1000 customers (Europe, North America, Asia and increasingly Africa).

Exports are carried out from our factory and our 3 marketing and sales offices in Europe.

For our printing partners, our microfibers are also available in plain colours, either in rolls or in cut pieces.

Strict quality control is applied at every stage of production

This quality control aims at :

All our products are cerified ISO 9001 & Reach-Oekotex and some of them are also certified GRS (Global Recycled Standard).

All our microfibers have been certified non-toxic since 2008 (EC N° 1272/2008 CLP).

The various certifications of our products are a guarantee of the high quality of our deliveries to our international customers who have given us their trust for many years in more than 100 countries where we export.

Most of our new products are produced in eco-friendly microfibers certified GRS (Global Recycled Standard).

The global market for advertising is growing steadily in most countries, prompting us to continually increase our R & D budgets for the creation of new products that meet perfectly the customer expectations in what has become a global market nowadays.

Our company strives to respect the environment in its production processes and constantly innovates to reduce waste and promote recycling.

Our actions are based on teamwork, initiatives, constant dialogue, the transmission

of know-how and the enhancement of collective intelligence. Our company is

committed to respecting all the copyrights of the works entrusted to it.

Our company regularly intervenes in educational, cultural and humanitarian projects thanks to the usefulness of its products necessary for the most deprived.

Building a long-term relationship with our customers is of utmost importance to us. Our company’s core values are built around the needs of our customers

1992: Creation of the company in June

1994: Creation of the International Department

1996: Trademark filings

2000: Creation of microfibers in digital transfer printing & Key Accounts Partnerships

2001: Expansion into the North American Market

2002: Patent Filings

2004: Relocation of the factory

2005: SME Export Award

2006: ISO 9001 Certification

2007: Development of machinery park knitting machines

2008: Awarded with the seal of excellence KOTRA (Korean Center for Foreign Trade)

2009: Certification REACH-Oekotex & Development of High Density Microfibers (75 Deniers)

2010: The Company changed its legal form to Corporation

2011: Moving the factory to more spacious and modern premises

2012: Creation of a subsidiary in Germany

2013: Implementation of the 50-foot container export for industrial manufacturers

2015: Creation of the UK subsidiary & growth development via the Internet

2016: Very active participation in International Trade Shows (PSI, MIDO, SILMO, CTCO, IOFT, NYVE, MEGA, HKOS, etc …)

2017: Preparation of social networks

2018: Implementation of the SEO strategy of the company

2019: Integration of new partners

2020: Working on the new interactive SEO website of the company

2021 : French-German Parnerpship in Humanitarian

2022 : Ecological Certification GRS (Global Recycled Standard)

2023 : Digital transformation of Dailytec

2024 : Completion of Dailytec’s digital transformation and preparation for AI integration

2025 : Launch of the new interactive website & Creation of two partnerships in India for local printing of our microfibres and direct deliveries to the Indian market

End 2025: Transfer of all activities from Lunettes sans Frontières – France to Brillen ohne Grenzen (Lunettes sans Frontières – Germany), which will become the European headquarters for all our international humanitarian activities in the field of optics from 2026 onwards.

Humanitarian partnership with “Eyewear with no frontier” Brillen ohne Grenzen –

Website : www.brillen-ohne-grenzen.de

Contact: Michael Roos – Mail: michael.roos@c-m-r.net

Partner of Lunettes sans Frontières (France) – Website : www.lunettes-sans-frontiere.fr

Contact: Jean-François Bonnard – Mail: lunettessansfrontiere@orange.fr

Free shipping of eyewear to various countries, and recently in 2024 and 2025 to DR Congo, Guinea Conakry and India. Development of free customized microfibers cleaning cloths for our humanitarian actions.

Our company is based in France, Germany, United Kingdom and South Korea in order to ensure a local service to its customers.

Head-Office

Dailytec-Kycloth, Ltd.

Unit 10-41 Breteuil

Parc d’Activités Saint-Maur

Rue du Buisson

F- 59800 LILLE (FRANCE)

Factory

Dailytec-Kycloth, Ltd.

20-8 Hwanseongjung-gil

880 Seobyung-Dong

BUK-GU

KR- 41477 DAEGU

CONTACT US

Tel. : + 33 – (0) 07 53 65 29 89

(voice mail : + 33 – (0) 3 20 42 12 85)

Whatsapp : + 33 – 7 53 65 29 89

Mail : contact@dailytec.com

www.dailytec.com – contact@dailytec.com

4 weeks (by air)

8 weeks (by sea)

Bank transfer

Free and with no commitment

24 hours